If you use medical instruments in a hospital or laboratory or produce them in a manufacturing facility, you need a dependable way to ensure their sterility. Sterile instruments protect patient health and provide accurate results in the lab setting, so reliable techniques are essential.

Autoclave sterilization is the superior, standard solution for effective sterilization of medical tools. Let’s explore autoclave uses, how the autoclave method works and how tools like aluminum cases and trays protect the instruments in the autoclave from damage.

An autoclave provides effective steam sterilization for medical tools like scalpels, forceps and other metal instruments, along with some types of glassware. The autoclave can also sterilize rubber-lined phenolic caps and polypropylene caps. Steam sterilizers kill microorganisms on the tools, making them safe for further medical procedures or laboratory work.

Autoclaves range dramatically in size. Some, like the ones used in many clinics, are small countertop machines about the size of microwaves. Others, like the ones in many large hospitals, are enormous stand-alone units that take up most of the space in a room.

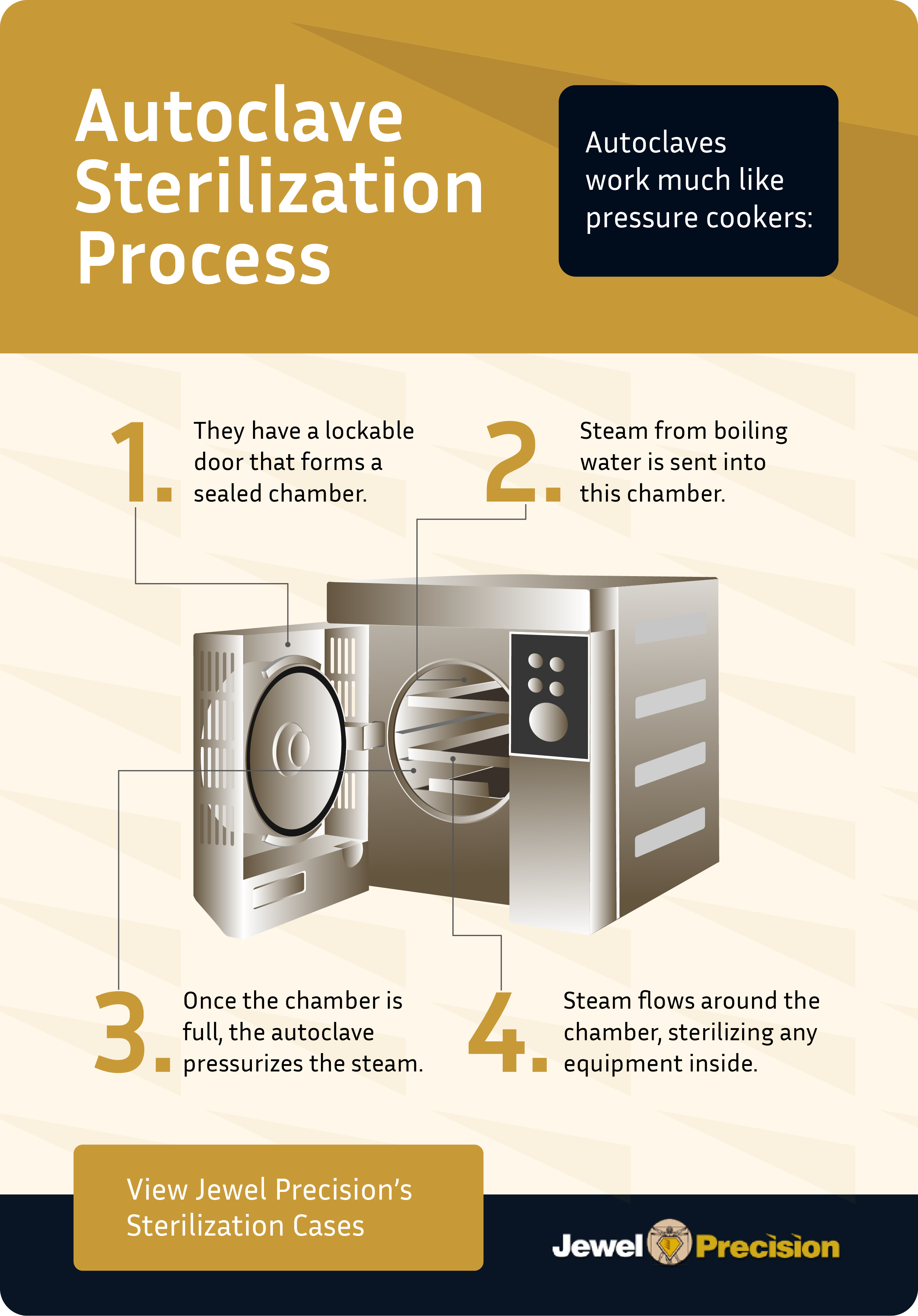

Whatever their size, autoclaves work much like pressure cookers. A steam autoclave contains a lockable door that forms a sealed chamber. It then boils water and sends the resulting steam into this compartment, replacing the air. Or, in some cases, an external generator produces the steam for use in the autoclave. Once the chamber is full, the autoclave pressurizes the steam, which then flows around the chamber, killing microorganisms to sterilize the equipment.

Why do autoclaves use steam rather than direct contact with boiling water? Killing microorganisms requires heating them to temperatures at which their cell walls break down and rupture. The challenge of using direct heat to do so is that air is a relatively inefficient means of heat transfer.

On the other hand, steam provides relatively efficient heat transfer. Additionally, creating steam by boiling water requires much more energy than merely heating water to its boiling point, so steam contains much more thermal energy than boiling water. It is much more effective at breaking down microorganisms when it transfers that thermal energy to them.

Autoclave Sterilization Temperature and Time

The Centers for Disease Control recommend standard autoclave sterilization temperatures of 121 degrees Celsius, or about 250 degrees Fahrenheit, and 132 degrees Celsius, or about 270 degrees Fahrenheit. In a gravity displacement sterilizer, the minimum exposure period for wrapped tools is 30 minutes at 121 degrees Celsius. In a pre-vacuum sterilizer, the minimum exposure period is four minutes at 132 degrees Celsius.

Various tools sometimes require different autoclaving temperatures and lengths of time spent in the autoclave, and they may require additional time if the facility desires higher sterility levels. The time and temperature requirements also sometimes differ for wrapped or enclosed versus unwrapped and unenclosed tools. You may need to check with the instrument manufacturers for guidance.

Why Is Autoclave Sterilization Necessary?

Clinical settings, especially hospital wards and emergency rooms, require sterile equipment to function. Autoclave sterilization is necessary because medical facilities need a reliable way to clean medical equipment between patients to prevent infection.

When patients go to the hospital, they expect to receive treatment for their injuries or illnesses — not to become sicker. However, the Centers for Disease Control report that at any given time, about one out of every 31 hospitalized patients has a hospital-acquired infection. Though using an autoclave cannot solve the challenges associated with antibiotic-resistant bacteria or airborne pathogens, it can prevent dangerous illnesses from spreading via reused medical tools. For instance, a patient undergoing surgery will have the peace of mind of knowing the scalpel used for the procedure is free from harmful contaminants.

Autoclave sterilization is also ideal in medical and laboratory settings because it is relatively eco-friendly. The autoclave consumes power as it runs. Still, it sterilizes tools effectively without harsh chemical reagents that are environmentally unfriendly and could pose health risks. It also enables the reuse of many different tools, eliminating disposable products and cutting down on waste.

Equipment Needed for the Autoclave Sterilization Process

For autoclave sterilization, a facility needs a way to contain and protect the tools undergoing sterilization. Some facilities use medical-grade paper or polypropylene wrappings around metal trays that hold the tools. Other facilities use durable, sealable metal sterilization cases. Sealed metal sterilization containers are unlikely to develop holes that could compromise the sterilization process. They also produce less waste than wrappings that go into the garbage after use. The advantage of using wrappings around metal trays is that they occupy less space and take much less time to wash, helping eliminate decontamination backlogs.

At Jewel Precision, our aluminum sterilization cases and trays come in three main types.

- Custom systems: With our custom systems, we design the sterilization cases and trays to your specifications, adding the features you need for optimal tool sterilization. These systems facilitate rapid autoclave cycle times and are durable enough to withstand the autoclave’s intense heat and steam.

- Modular systems: With our modular systems, you’ll get brackets with convenient inserts and locating pins. You can add these to your cases and trays as needed to create a suitable layout for holding instruments securely in place.

- Rigid reusable systems: We optimize our rigid reusable systems for superior toughness and durability. They offer complete coverage of your medical tools, so you’ll have no disposable wrappings to throw away after sterilization.

Effect on Sterilization Cases

When you depend on your autoclave, high-quality, durable sterilization cases are critical. Fortunately, we’ve designed our cases to endure the sterilization process without corroding or deteriorating over time.

For instance, consider our rigid reusable systems. We test them under the most intensive autoclave conditions, sterilizing them in 270-degree steam for four minutes while fully loaded with medical instruments. They easily pass our stringent criteria under those circumstances, demonstrating their durability for the rigors of medical or manufacturing use.

Dependable Sterilization Cases and Trays From Jewel Precision

When you need reliable autoclave protection for your medical instruments, trust Jewel Precision for dependable solutions. The superior quality of our cases means they’ll protect your tools through many autoclave sterilization cycles. Our short lead times, competitive pricing and diligent, friendly customer service also mean you’ll get the cases and trays you need when you need them. You can trust us for knowledgeable, helpful answers to your questions.

Contact us today to get a personalized quote for autoclave sterilization cases or learn more.